Machinery Troubleshooting

RITEC is famous for troubleshooting machinery problems particularly during start-up.RITEC service teams can use a variety of tools to troubleshoot machinery problems.

Causes of Machinery problems may be induced by design, operation, installation/maintenance and/or wear and tear.

By using Portable Multi-Channel Parallel Data Acquisition Systems and acquiring data from existing sensors, through an online monitoring system, or by supplying the sensors (Accelerometers, Piezo-Electric Velocity or Eddy Current Sensors), RITEC can acquire advanced vibration data necessary for diagnosing machinery problems.

Run-Up/Run-Down, Shaft Centerlines, Orbits (filtered and unfiltered), Spectra, Full Spectrum, Time-Waveforms, Cross-Channel, Resonance/Critical Speed Testing, and various other measurements aid in identifying the causes and effects of the vibration problems.

Furthermore, RITEC, using its own in-house developed Rotordynamics Analysis Software (RIMAP), conducts rotordynamic analysis to study machinery dynamic characteristics and remedy chronic machinery problems.

RITEC uses rotordynamic analysis to identify: Critical Speeds, Mode Shapes, Unbalance Response, Deflection Shapes of Rotating Machinery and Rotordynamic analysis can be used to alleviate: Resonance problems, Sensitivity to unbalance, stability problems, as well as many other rotating machinery problems.

RITEC uses rotordynamic analysis to modify existing machines to overcome rotordynamic problems.

Visit our Library & Tools page to read more about our troubleshooting cases.

For more information, please contact us.

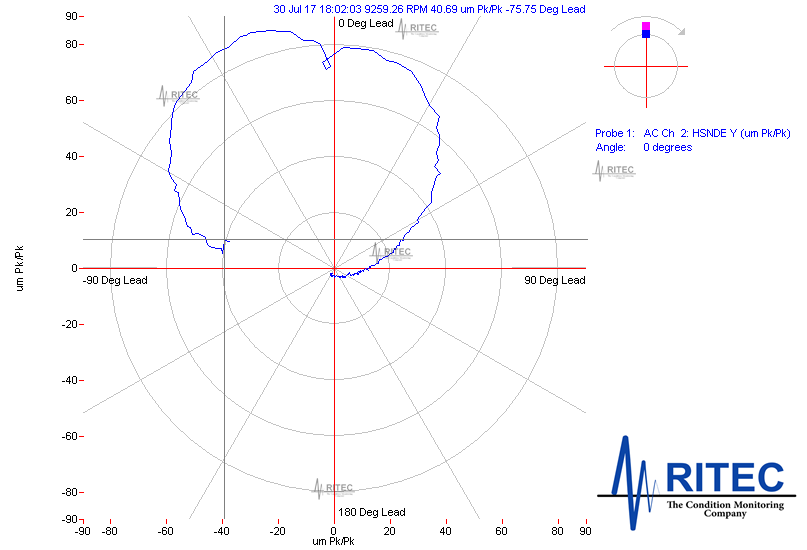

Polar Plot showing Resonance

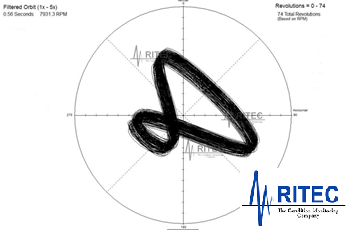

Polar Plot showing Resonance Orbital Plot showing Misalignment

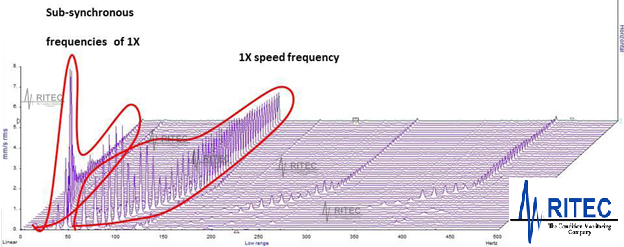

Orbital Plot showing Misalignment Waterfall Plot showing Instability

Waterfall Plot showing Instability

RITEC Services

Vibration Analysis

Condition Monitoring

Motor Current

Ultrasound

Motion Magnification

Thermal Imaging

In-Situ Balancing

Alignment

Troubleshooting

Reliability At SeaTM

Acceptance Testing

Modal/ODS Analysis

Rotordynamic Analysis

Vibration Control

Structural Vibration

Noise & Sound

Calibration