Machinery/Shaft misalignment is considered as a major contributing factor to machinery components accelerated wear and tear. Mis-aligned machinery may exhibit: excessive machinery vibration, elevated bearing temperatures, leakage of bearing seals, and premature bearing, seal and coupling failure.

Precision maintenance of machinery through Shaft Alignment reduces excessive forces and stresses on the various machinery components. This leads to increases in the fatigue life (L10) of machinery components, and ultimately improves the reliability, availability and uptime of the machine.

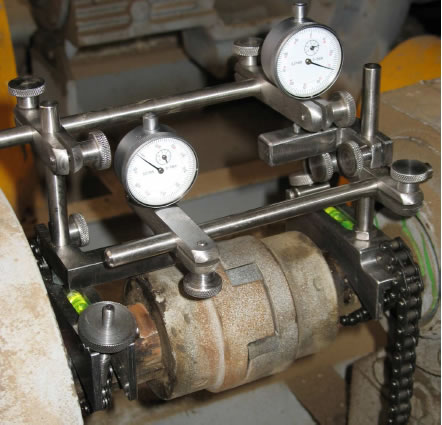

RITEC conducts shaft alignment of machinery using both Dial Guage Indicators, as well as, Laser Alignment. RITEC's teams of Alignment Specialists conduct thorough inspections and evaluations of Soft Foot, Piping Strain, Run-out, and Thermal Growth. RITEC can carry out Laser Alignment of Pulleys, as well as, Rolls. Furthermore, RITEC can provide Geometeric Alignment Tests: i.e. Flatness, Levelness, Squareness etc.

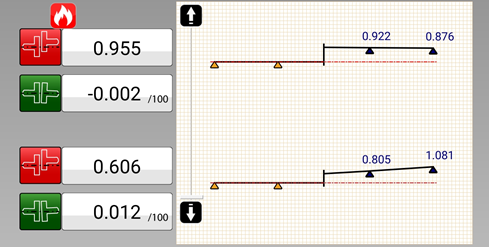

RITEC conducts shaft alignment of machinery using both Dial Guage Indicators, as well as, Laser Alignment. RITEC's teams of Alignment Specialists conduct thorough inspections and evaluations of Soft Foot, Piping Strain, Run-out, and Thermal Growth. RITEC can carry out Laser Alignment of Pulleys, as well as, Rolls. Furthermore, RITEC can provide Geometeric Alignment Tests: i.e. Flatness, Levelness, Squareness etc.RITEC develops and markets its own Dial Indicator Alignment Kit (RITE-Align) with Alignment Software, to carry out Reverse and Face & Rim Methods. Finally, RITEC conducts hands-on practical alignment training courses.

RITEC Services

Vibration Analysis

Condition Monitoring

Motor Current

Ultrasound

Motion Magnification

Thermal Imaging

In-Situ Balancing

Alignment

Troubleshooting

Reliability At SeaTM

Acceptance Testing

Modal/ODS Analysis

Rotordynamic Analysis

Vibration Control

Structural Vibration

Noise & Sound

Calibration