NFPA 70B states that "routine infrared inspections of energized electrical systems should be performed annually prior to shutdown. More frequent infrared inspections, for example, quarterly or semiannually, should be performed where warranted by loss experience, installation of new electrical equipment, or changes in environmental, operational, or load conditions.”

RITEC's team of specialists conducts thermography surveys. Annual Surveys are important for Electrical Equipment: Switchboards, Panel Boards, Panel Boxes, PDU's, Bus Ducts, Power Cabling, Control Panels, Cable Terminations, Transformers (air and oil), Fuse Disconnects and holders.

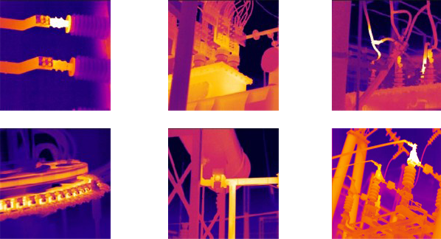

Thermographic surveys are conducted on a magnitude of Electrical and Mechanical

equipment and aid in preventative condition monitoring.

Electrical Equipment:

RITEC's team of specialists conducts thermography surveys. Annual Surveys are important for Electrical Equipment: Switchboards, Panel Boards, Panel Boxes, PDU's, Bus Ducts, Power Cabling, Control Panels, Cable Terminations, Transformers (air and oil), Fuse Disconnects and holders.

Thermographic surveys are conducted on a magnitude of Electrical and Mechanical

equipment and aid in preventative condition monitoring.

Electrical Equipment:

- Switchboards

- Panel Boards

- Panel Boxes

- PDU's

- Bus Ducts

- Power Cabling

- Control Panels

- Cable Terminations

- Transformers (air and oil)

- Fuse Disconnects and holders

- Pumps

- Motors

- Shaft Couplings

- Air duct blockage

- Oil Cooling Channels

RITEC Technical Services

Vibration Analysis

Condition Monitoring

Motor Current

Ultrasound

Motion Magnification

Thermal Imaging

In-Situ Balancing

Alignment

Troubleshooting

Reliability At SeaTM

Acceptance Testing

Modal/ODS Analysis

Rotordynamic Analysis

Vibration Control

Structural Vibration

Noise & Sound

Calibration