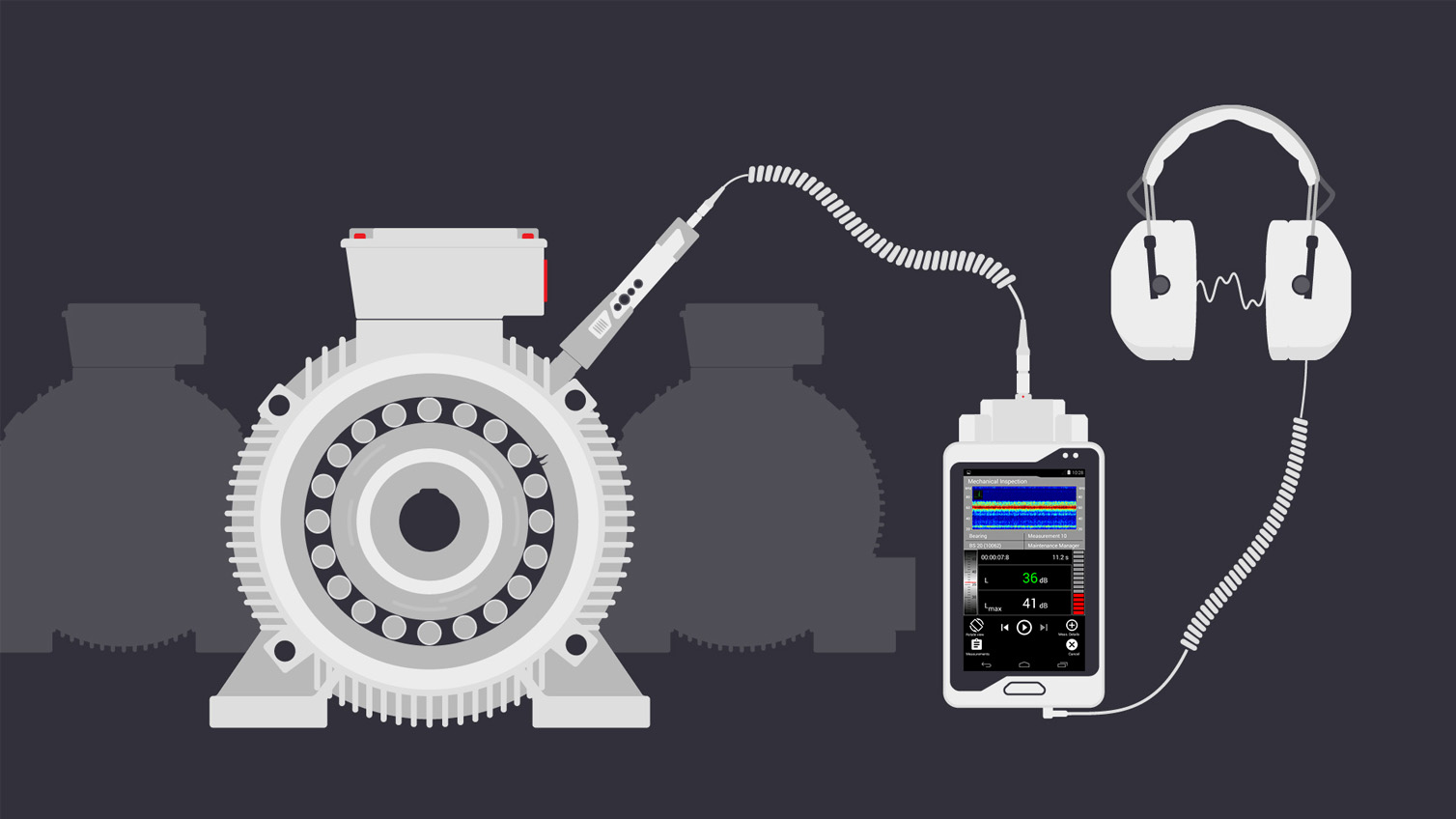

Bearing Monitoring & Lubrication

A regular condition based monitoring of bearings is essential for a successful preventative maintenance. The early detection of damages or signs of wear in friction and non-friction bearings leads to prevent downtime, increased operational reliability and considerable cost savings.

An ultrasonic testing device for bearing testing can also be used in order to check the lubrication and friction level, to interpret defect induced noises and for the preventive inspection of pumps and compressors. In the case of rotary pumps it also allows the possibility of detecting cavitation noises.

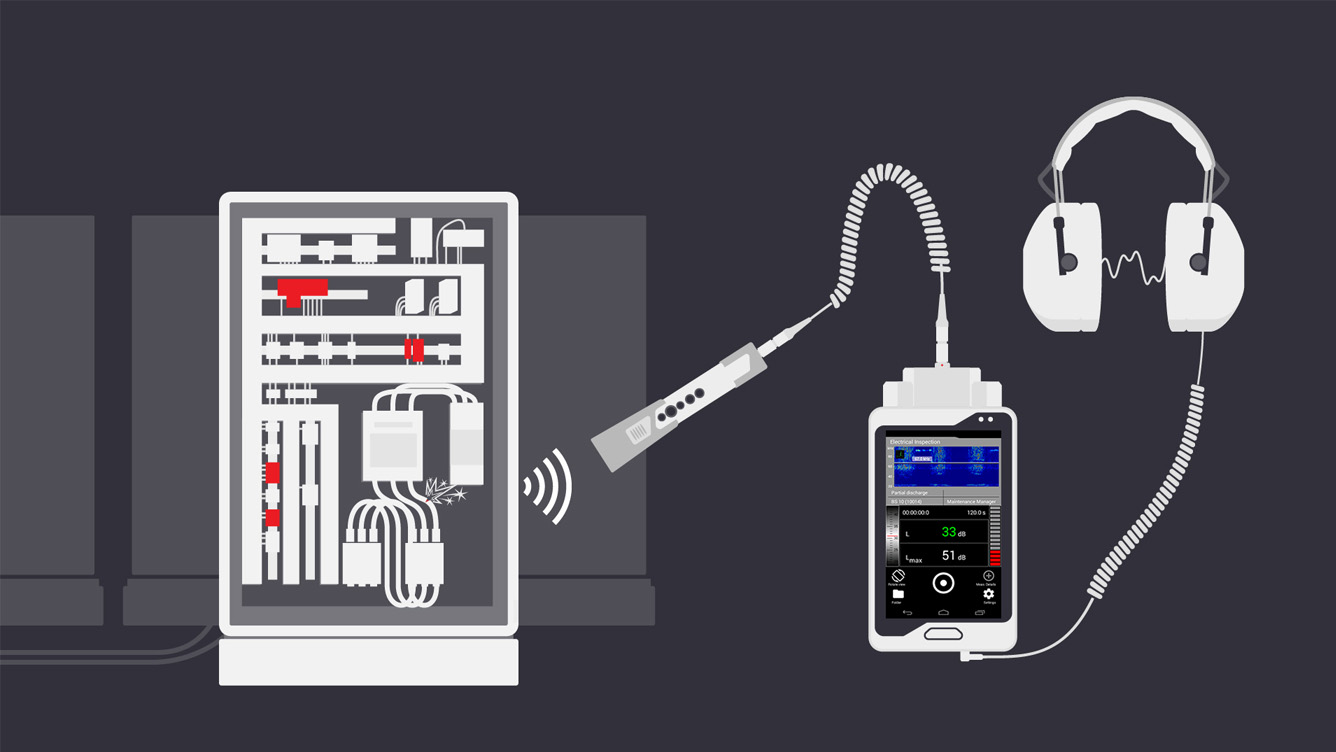

Detection of Partial Discharges

The regular inspection of equipment is essential for preventative maintenance. The early detection of electrical partial discharges like corona, tracking or arcing leads to increased operational reliability, considerable cost savings and safety.

A specialized parabolic dish detects damage that is difficult to reach or far away e.g on transmission and distribution lines. The high sensitivity and the precise directionality of the sensor allow the detection of electrical partial discharges and damage at electrical insulations on e.g. medium-voltage equipment or switchgears.

Leak Detection

Nowadays the saving of energy is an important topic in all areas in which compressed air systems are used. Finding and eliminating leaks in compressed air systems alone can save up to 35 % of the energy costs associated with the use of a compressor.

RITEC uses the SONOTEC ultrasonic leak detector which is designed for quick and precise location of leaks in compressed air, inert gas and vacuum systems. System leaks can easily be detected. The variety of devices in the range and the extensive accessories available enable this range of devices to be used for a multitude of various applications.

To find leaks over long distances, the parabolic dish is able to locate leaks up to a range of 20m.

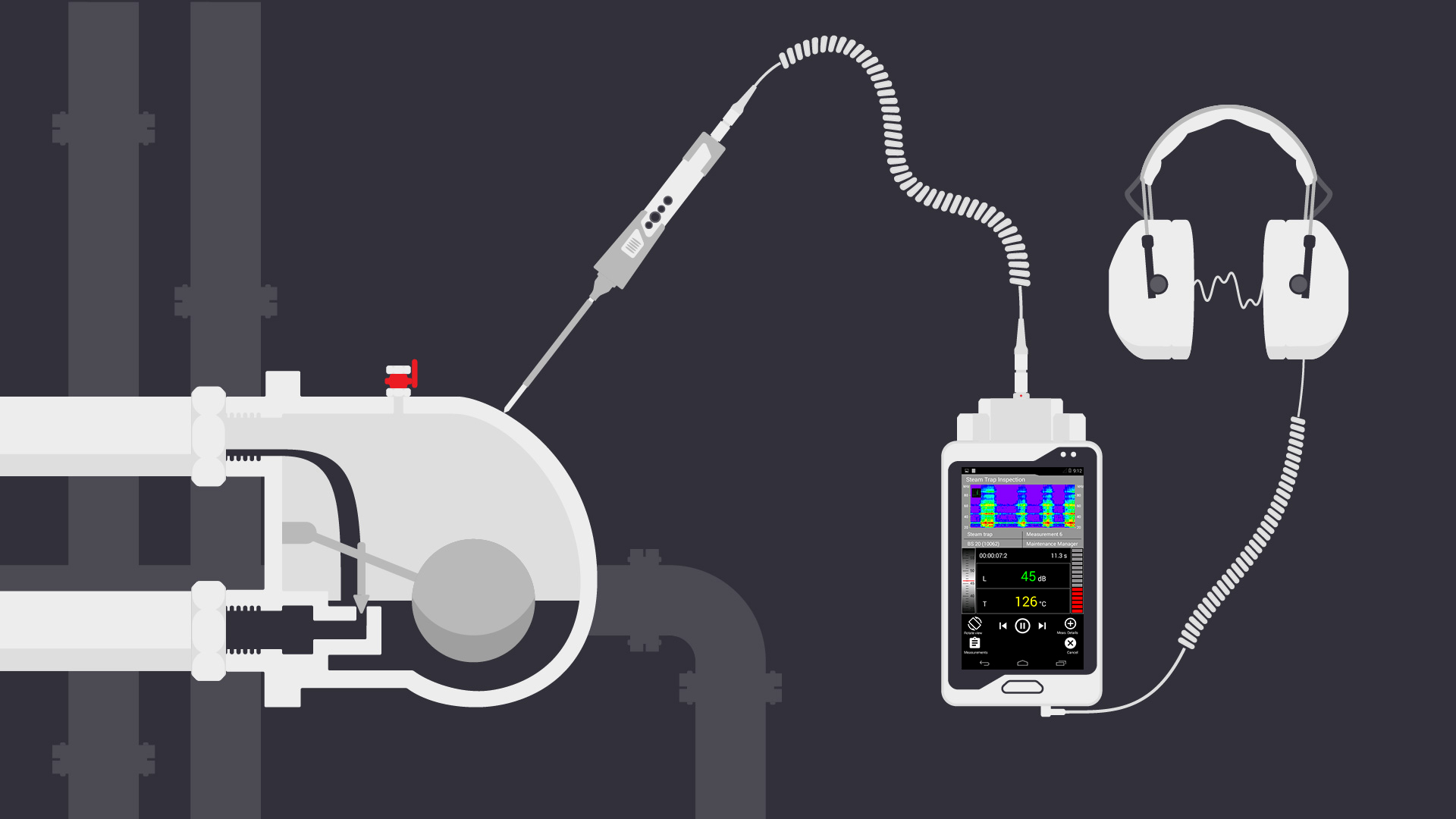

Steam Trap & Valve Inspection

The regular inspection of valves and steam traps is essential for preventive maintenance. The early detection of steam trap leaks or failures and signs of wear leads to increased operational reliability, and considerable cost savings.

The SONOTEC ultrasonic testing device is used for steam trap and valve inspections in many branches of industry. Ultrasonic testing devices can be used for the testing of the functionality of any type of steam trap e.g. for float, thermodynamic and thermostatic traps or for valves in systems with a flow of steam. The device enables the control of the proper functionality of steam traps and also allows an estimation of any losses of steam within the system.

The functionality of steam traps and valves is tested by analysing the typical ultrasound and temperature of the respective installation.

RITEC Technical Services

Vibration Analysis

Condition Monitoring

Motor Current

Ultrasound

Motion Magnification

Thermal Imaging

In-Situ Balancing

Alignment

Troubleshooting

Reliability At SeaTM

Acceptance Testing

Modal/ODS Analysis

Rotordynamic Analysis

Vibration Control

Structural Vibration

Noise & Sound

Calibration