-

Vibration Analysis

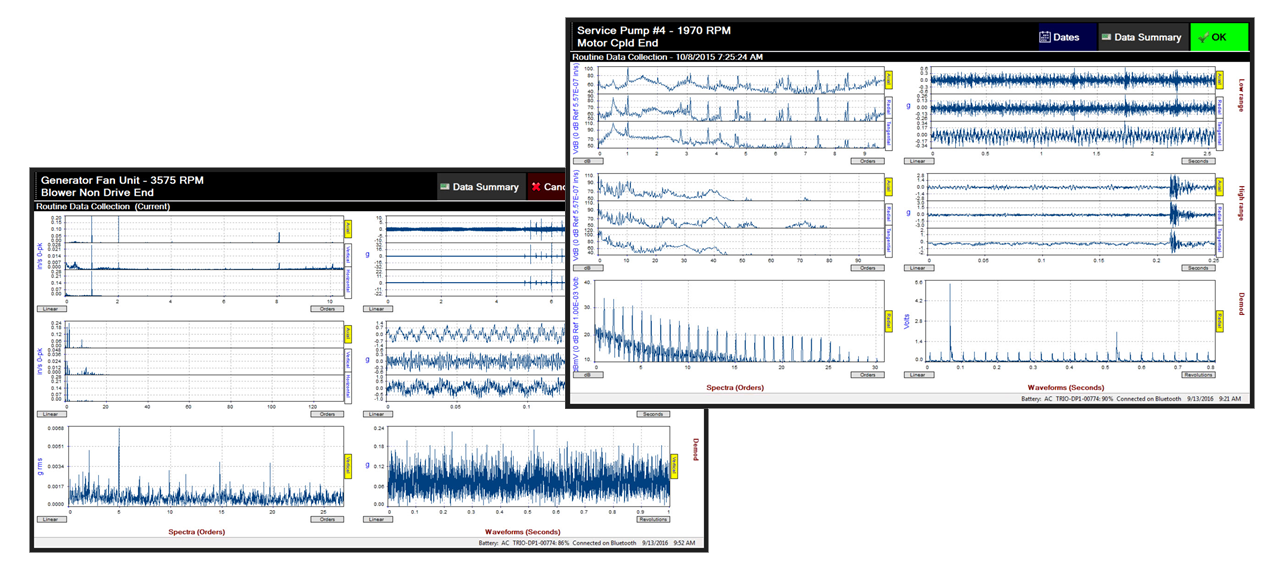

Vibration as the main field of RITEC’s activities, has traditionally been associated with trouble in machines-wear, malfunction, noise, and structural damage. In more recent years, however, vibration has been used to save industry millions of dollars in machine downtime. Evaluation of changes in levels of machine vibration has become an important part of most maintenance programs. Similar evaluations are used to solve design problems as well as to establish the cause of chronic malfunctions and failures.

-

Condition Monitoring

Through the periodic collection of relevant dynamic (e.g. Vibration) and process data of a given asset, RITEC's teams of analysts can determine the current condition, as well as infer the remaining useful life of a machine (or its subcomponents). This allows Maintenance teams to optimize scheduling and planning of maintenance intervals and spare parts, as well as increase uptime and reliability.

-

Vibration Motion Magnification

VibVueTM Magnifies Vibrating Motion by Thousands to the Human Visual Threshold. It is Capable of Full Machine View at Frequencies up to 640 Hz, Powerful and Intuitive Diagnostic Tool, Does Not Require Contact, Ideal for Restricted Areas, Fast & Cost Effective, Based on Decades of Troubleshooting Experience, User-friendly Interface, Customizable for Individual Solutions. -

Motor Current

Motor Current Signature Analysis (MCSA) is an integral component for the condition monitoring of electric drivers. Through the collection of the input current in a loaded state, insight into the condition of an induction motor's components such as rotor bar can be deduced. This non-intrusive technique, allows for online evaluation of an electrical machines condition without the need for stoppage.

-

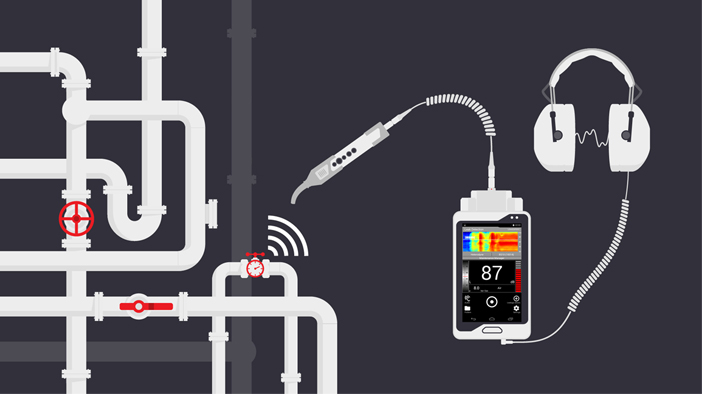

Ultrasound

Ultrasound testing enables the detection of: Air Leaks in compressed air systems, Bearing Lubrication Problems, Partial Discharge in electrical systems, as well as Steam Trap and Valve Testing.

-

Thermal Imaging

RITEC's team of specialists conducts thermography surveys.

All surveys conform with British Standard 7671.

Thermographic surveys are conducted on a magnitude of equipment and aid in preventitive condition monitoring.

-

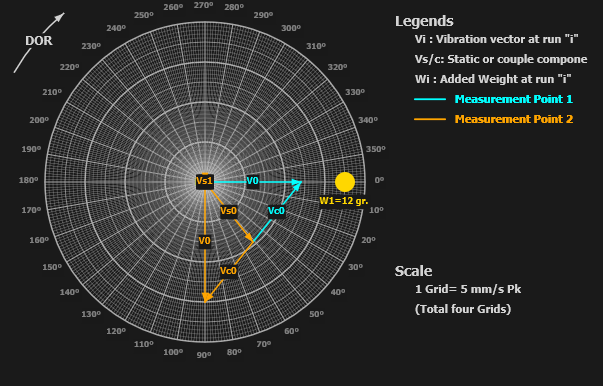

In-Situ Balancing

RITEC is the only Middle Eastern company capable of balancing flexible rotors.

RITEC is famous for using Single-Shot methods to balance repeat machines.

RITEC mostly uses Static-Couple techniques to balance machines.

RITEC balances machines and machine trains to ISO tolerances.

-

Alignment

RITEC conducts alignment of machines and machine trains using both Dial Indicator and Laser alignment tools.

RITEC uses techniques to compensate for sag and thermal growth in the alignment methods.

RITEC also provides Parallel Roll Alignment, Pulley Alignment, and geometric flateness and levelness measurements.

-

Troubleshooting

RITEC is famous for troubleshooting machinery problems particularly during start-up.

RITEC service teams can use a variety of tools to troubleshoot machinery problems.

-

Reliability At SeaTM

RITEC provides the latest in condition monitoring technology to monitor vibrations of on-board machinery by utilizing the only proven Expert Diagostics System, developed by Azima DLI for the US Navy.

RITEC can remotely monitor and provide timely alert for degredation in a ships machinery including: Engines, Gearboxes, Stern Tubes & Shafts, Auxillary Equipment & others. Service is applicable to Sea/Ocean going as well as inland vessels.

-

Acceptance Testing

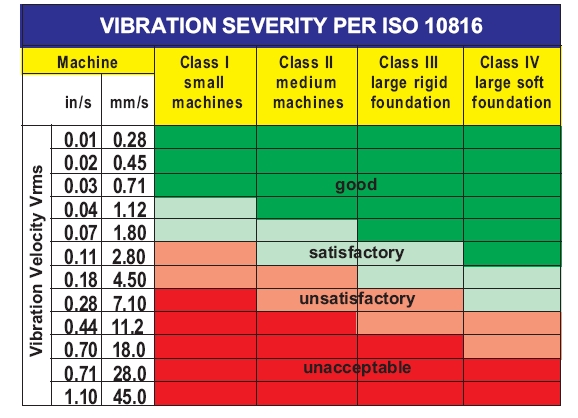

RITEC team of ISO-18436 certified vibration analysts perform new/newly repaired machine acceptance testing according to ISO and API standards.

Wide variety of tools and instrumentation available. Documentation of machine Balance condition and baseline.

-

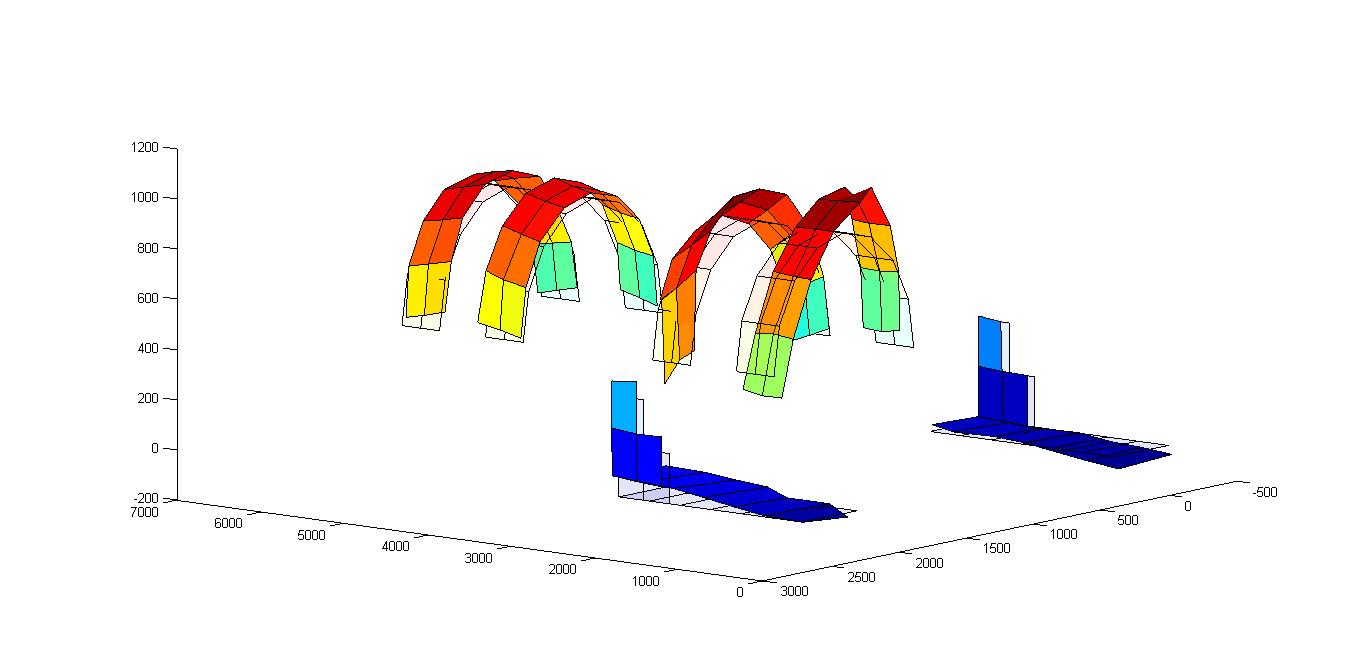

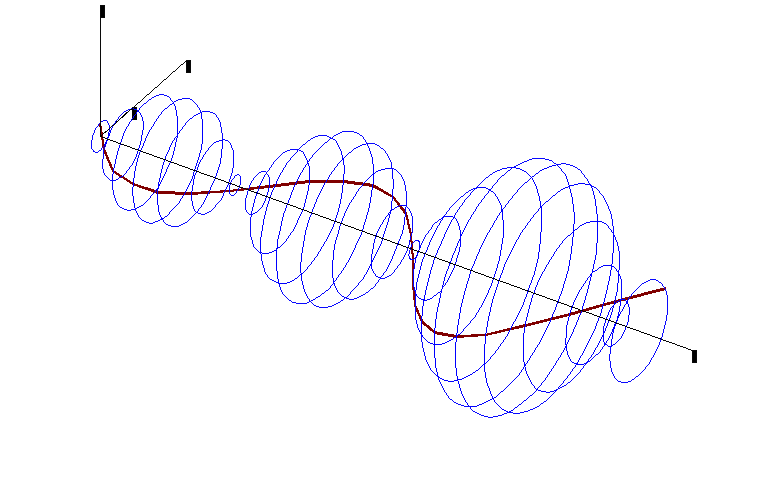

Modal/ODS Analysis

RITEC carries out advanced vibration measurements to obtain dynamic charachteristics of structures and/or machinery.

RITEC uses these measurements to extract useful system charachteristics such as: damping and natural frequencies.

-

Rotordynamic Analysis

RITEC conducts rotordynamic analysis to study machinery dynamic characteristics and remedy chronic machinery problems. RITEC uses rotordynamic analysis to identify: Critical Speeds, Mode Shapes,Unbalance Response, and Deflection Shapes of Rotating Machinery RIMAP.