The SONOTEC GmbH is a leading specialist in ultrasonic measurement technology solutions. With more than 165 employees, the technology company based in Halle (Saale) develops and manufactures customer-specific ultrasonic transducers and sensors as well as testing equipment and measuring technology solutions for preventive maintenance, non-destructive testing, medical technology and biotechnology.

In most factories, regular preventive maintenance is performed to reduce machine failures, increase plant availability and to save energy costs.

With the multi-purpose ultrasonic testing devices of the SONAPHONE family, many of these tasks can be carried out quickly and efficiently.

The operation is simple and extensive trainings are no longer needed.

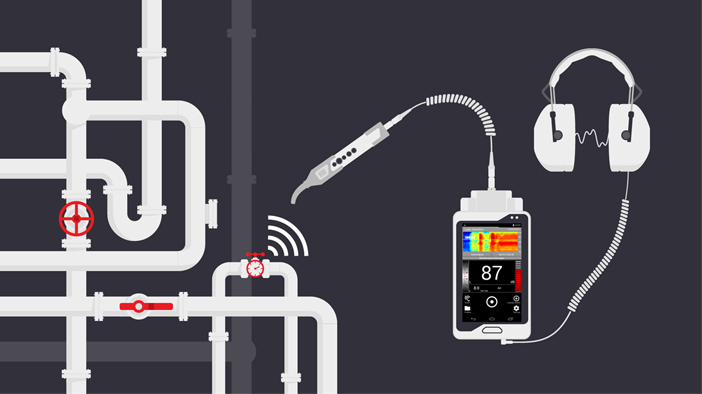

The SONAPHONE devices detect leakages in compressed air, gas and vacuum systems.

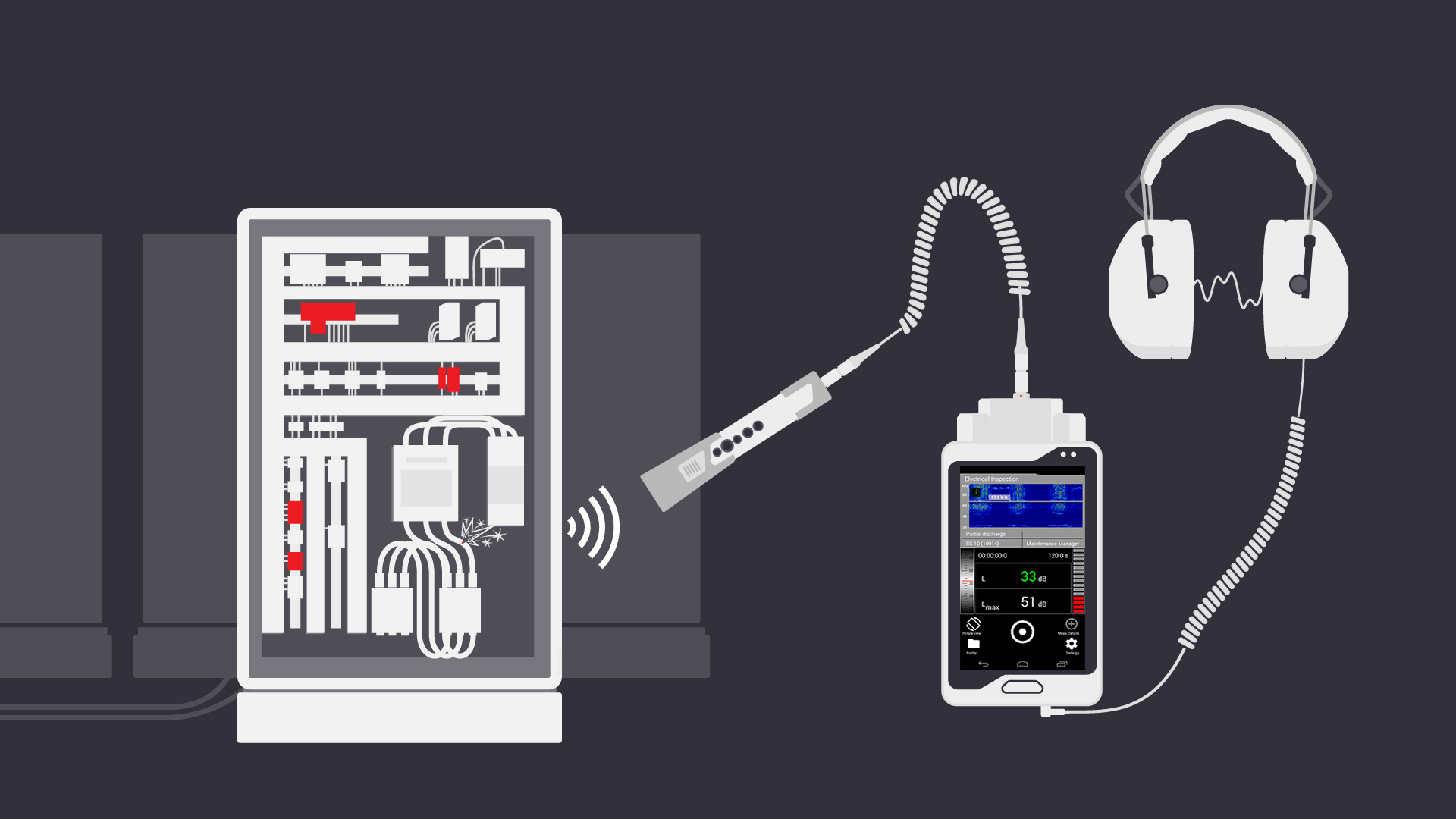

They reliably inspect bearings, the functioning of valves as well as steam traps and detect electrical partial discharges on medium or high-voltage equipment.

By applying an ultrasonic transmitter the SONAPHONE devices can also be used for tightness testing of cabins, hatch covers, containers and other pressureless systems.

SONAPHONE product family can be used for:

- Leak Detection

- Steam Trap & Valve Inspection

- Bearing Monitoring & Lubrication

- Tightness Testing

- Partial Discharge Detection

Machine Testing with SONAPHONE

Steam Trap Testing with SONAPHONE

Detection of Partial Discharges with SONAPHONE

Leak Detection and Evaluation with SONAPHONE

Unique Innovations In SONAPHONE

TOUCHSCREEN TECHNOLOGY

The SONAPHONE can be operated intuitively like a tablet via 5-inch display with multi-touchscreen. Even new employees and service providers master the extremely comfortable handling quickly and can perform test processes themselves after just brief introduction.

.jpg)

BROADBAND ULTRASONIC ANALYSIS

With the new SONAPHONE maintenance staff can see and hear everything that happens in the frequency range from 20 to 100 kHz. In contrast only a narrow frequency range can be gathered with comparable testing technology. By integrating new sensors, innovative measurement technology and advanced data processing, SONOTEC has successfully provided a completely new analysis of the ultrasonic signal, which is unrivalled on the market. This makes new applications like leak classifi cation possible..jpg)

FROM PROBE TO DIGITAL SENSOR

The sensors from SONOTEC not only differ visually from the airborne and structure-borne sound probes that are usual on the market – processes run in the sensor itself which contrast significantly with the previously known narrowband technology. Thus the broadband sensors simultaneously receive and process ultrasonic signals from 20 to 100 kHz. The additional information obtained in this way is very significant for the evaluation of the condition of machines and systems and paves the way for new applications in maintenance 4.0.

.jpg)

.jpg)