Beran PlantProtech™ Condition Monitoring Systems are in use around the world within numerous power generation companies, including coal, oil, gas-fired, nuclear and hydro. The plant items monitored include steam turbines, gas turbines and water turbines, pumps, fans, compressors and coolant circulators. Beran TransCal™ Transducer Calibration Systems are in service with many European and USA automotive, aerospace and power generation companies, along with Certified Calibration Houses, meeting the ISO 16063-21 requirement for transducer calibration.

Beran Frequency Response Analysers are employed in the verification of many aircraft and control systems.

PlantProtech™ is Beran's platform for condition monitoring of rotating machinery, built on over twenty

years of industrial experience and innovation.

The PlantProtech hardware / software family is in use throughout the world, with over 300 systems currently being utilised within the power industry. The PlantProtech range is installed on Nuclear, Fossil, Hydro, CCGT and Combined Cycle industrial plant.

Originally designed to meet the requirements of the Central Electricity Generation Board (CEGB) VCM/7 specification, our PlantProtech systems have been proven to pay for themselves many times over. As user requirements have increased, the PlantProtech range has developed accordingly.

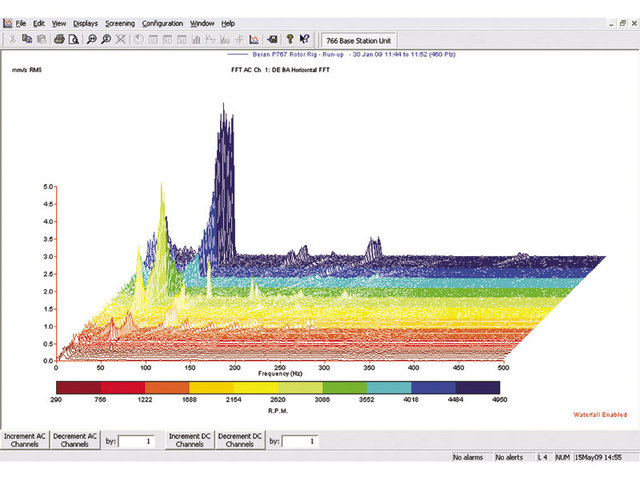

By means of continuous on-line vibration monitoring, changes in the health of the plant may be detected early. Powerful analysis tools allow the root cause of the problem to be identified, allowing operators to make crucial decisions, in many cases allowing their plant to be run with confidence at reduced load through to planned outage / scheduled maintenance.

The PlantProtech range of hardware and software products provides you with a solid foundation, which can be added to and expanded as and when required, ensuring the safety of your investments.

Real-Time

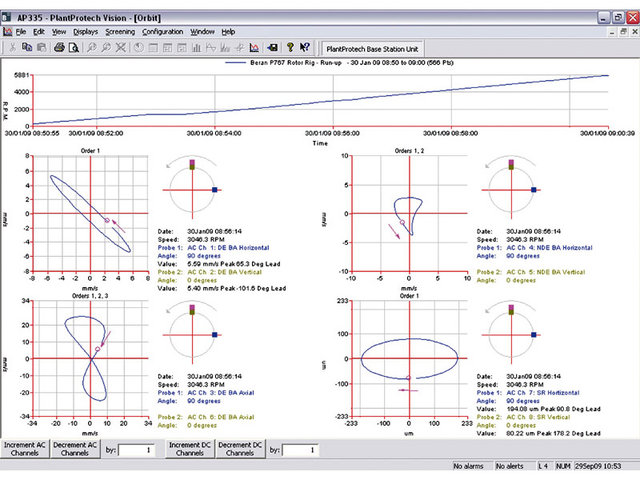

PlantProtech real-time capability allows you to analyse the machine state in real-time on-screen, as it is happening, allowing direct correlation with other Station protection equipment and process data.

Parallel Analysis

Parallel data acquisition is important to enable the user to understand the full dynamic behaviour of the machine. Beran PlantProtech Analysers feature parallel dynamic acquisition for both steady-state and variable speed plant modes, with simultaneous measuring of vibration and process parameters.